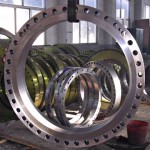

Types of Flanges for Heat Exchangers

Heat exchangers transfer heat from one fluid to another. They operate air conditioners, condensers, evaporators, refrigerators and boilers. Heat exchanger flanges are rings or rims that connect to pipes, valves, pumps and other equipment to add strength and secure, isolate or attach components. Flange materials are typically steel, iron, aluminum, bronze or plastic. Common flange types include weld neck, slip-on, blind, threaded and socket weld flanges.

Weld Neck Flanges

Weld neck flanges are also called welding neck flanges. They have a raised face and a long tapering or beveled hub. The wall thickness of the flange is the same dimension as the pipe to which it is attached and the flange’s bore diameter matches that of the attaching pipe as well. This helps minimize fluid turbulence and erosion. Fabricators butt-weld these flanges to pipes around the circumference of their neck. Weld neck flanges have the highest safety factor and fatigue strength, making them useful for a broad variety of applications, especially for those under extreme pressures and temperatures.

Slip-On Flanges

Slip-on flanges slip over the end of a pipe. The bore diameter of the flange is slightly larger than that of the piping over which it slips. Fabricators weld them in place on both interior and exterior flange faces. This helps prevent leaks. Slip-on flanges have a lower upfront cost and require less accurate pipe cutting, and present less difficulty aligning bolt holes and squaring flange faces. Fabricators typically maintain a slight space between the flange and the pipe when connecting them. Manufacturers do not recommend using them in high-temperature applications.

Blind Flanges

Blind flanges, also called blank flanges or blanking flanges, are solid plate fittings that do not have a bore through their center. They seal off flow in a pipe, valve or pump, closing off the end of a system. Blind flanges do not have drilled bolt holes, but manufacturers sometimes machine them slightly to receive the end of a pipe. Blind flanges can also function as covers, providing a convenient portal for pipe or system inspection, cleaning or maintenance.

Threaded Flanges

Threaded flanges, also called screwed flanges, connect threaded components to one another. They consist of grooved rings with either an internal or an external threading. This allows the flange to mate with standard threaded piping. Threaded flanges do not require welding, and therefore are best for applications where leakage through threads will not adversely affect the system. In general, they are preferable in low-pressure, noncritical applications, particularly at or near atmospheric temperature.

Socket Weld Flanges

Socket weld flanges have a bore and a counter bore. The flange counter bore is larger than the outer diameter of the pipe for easy pipe insertion. The pipe rests against the bottom of the bore. Fabricators weld the flange to the pipe on the interior and exterior sides. The interior diameters of both the flange and the pipe are the same to minimize fluid flow turbulence. Manufacturers recommend a slight gap between the pipe end and the shoulder of the socket for expansion.