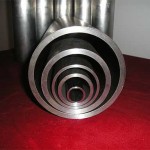

DIN/EN steel pipe

DIN/EN seamless pipes are extensively applied in petroleum, chemical, power, boiler, and machinery industries. Our prefect products and preferential price have won us customers’ trust and consistently favorable comments.

- Metal Pipes

- DIN17175 steel Pipe

- DIN1629 steel pipe

- DIN2391 Seamless Tube

- Pipe Threading

- EN 10305-1 Precision Tube

- EN 10216-2 Boiler Tubes

- EN 10216-1 Pressure Tubes

- U-bend seamless tube

Dimension tolerance

| Standard | Tolerance | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Out side Diameter | Wall Thickness | Length | ||||||||

| mm | ||||||||||

| DIN 1630 | SeeTable 1 | SeeTable 2 | SeeTable 3 | |||||||

| DIN 2391 | SeeTable 4 | 10% | SeeTable 5 | |||||||

| DIN 2440 | SeeTable 6 | -12.5%, + A | 1m | |||||||

| DIN 2441 | SeeTable 2 | -12.5%, + A | 1m | |||||||

| DIN 17172 | SeeTable 7 | 130 | 10% | Fixed Length |

500 | |||||

| >130 | 12.5% | |||||||||

| DIN 17173 | SeeTable 1 | SeeTable 2 | SeeTable 3 | |||||||

| DIN 17175 | SeeTable 1 | SeeTable 2 | SeeTable 3 | |||||||

| DIN 17176 | SeeTable 8 | SeeTable 2 | SeeTable 3 | |||||||

| DIN 17179 | SeeTable 1 | SeeTable 2 | SeeTable 3 | |||||||

| DIN 28180 | Outside Diameter |

Class 1 | Class 2 | Class 3 | SeeTable 9 | 5000 | -0,+5 | |||

| 16-30 | 0.08 | Not Applicable |

0.50 | >5000 -10000 |

-0,+10 | |||||

| 38 | 0.15 | >10000 | By agreement |

|||||||

| A: The upper Limit is fixed by the permissible weight deviation. | ||||||||||

Table 1: Permissible Deviation in Outside Diameter in DIN 1630, 17173, 17175, 17179

| Outside Diameter – da mm |

Pertilisable Deviation in Diameter | |

|---|---|---|

| Tube Barrel and Tube Ends | At Tube ends, Subject to Particular agreement |

|

| <100 | 1% da; (values up to 0.5mm are permitted) |

0.4mm |

| 100a<200 | 1% da | 0.5% da. |

| 200 | 1% da | 0.6% da |

Table 2: Permissible Deviation in Wall Thickness in DIN 1630, 17173, 17175, 17176, 17179

| Permissible Deviation in Wall Thickness for Outside Diameter, da. and Wall Thicknesses, s | ||||||||

|---|---|---|---|---|---|---|---|---|

| dia 130mm | 130mm<da320mm | 320mm<da660mm | ||||||

| s 2 | 2<s4 | s>4 | s0.05da | 0.05da<s .11da |

s>0.11da. | s0.05da | 0.05da<s 0.09da |

s>0.09da |

| +5% -10% |

+12.5 %10 |

9% | +17.5% -12.5% |

12.5% | 10 | +20% -15% |

+15% -12.5% |

+12.5% -10% |

Table 3: Types of Length and Permissible Deviation in Length in DIN 1630, 17173, 17175, 17176, 17179

| Type of Length | Premissuble Deviations in Length,mm | |

|---|---|---|

| Manfacturing Length | By agreement | |

| Specified Length | 500 | |

| Exact Length |

6m | -0,+10 |

| >6-12mm | -0,+15 | |

| >12m | By agreement | |

Table 4: Permissible Deviation in Outside Diameter in DIN 2391

| Outside Diameter |

Permissible Deviation |

Outside Diameter |

Permissible Deviation |

Outside Diameter |

Permissible Deviation |

||

|---|---|---|---|---|---|---|---|

| 4-10mm | 0.08mm | 75-81mm | 0.35mm | 170-180mm | 0.90mm | ||

| 12-30mm | 0.1mm | 85-90mm | 0.40mm | 190-200mm | 1.0mm | ||

| 32-40mm | 0.15mm | 95-100mm | 0.45mm | 220-240mm | 1.20mm | ||

| 42-50mm | 0.20mm | 110-12mm | 0.50mm | 260mm | 1.30mm | ||

| 55-60mm | 0.25mm | 130-146m | 0.70mm | ||||

| 65-70mm | 0.30mm | 150-160m | 0.80mm |

Table 5: Types of Length and Permissible Deviation in Length in 2391

| Type of Length | Premissuble Deviations in Length,mm | ||

|---|---|---|---|

| Manfacturing Length | By agreement | ||

| Fixed Length | <2000 | 500 | |

| 2000 | 10% | ||

| Exact Length |

<500mm | -0,+2 | |

| >500-2000mm | -0,+3 | ||

| >2000-5000 | -0,+5 | ||

| >5000-7000 | -0,+10 | ||

| >7000 | By agreement | ||

Table 6: Permissible Deviation in Outside Diameter in DIN 2440, 2441

| Outside Diameter (mm) |

Max (mm) |

Min (mm) |

Outside Diameter (mm) |

Max (mm) |

Min (mm) |

|

|---|---|---|---|---|---|---|

| 10.2 | 10.6 | 9.8 | 48.3 | 48.8 | 47.9 | |

| 13.5 | 14.0 | 13.2 | 60.3 | 60.8 | 59.7 | |

| 17.2 | 17.5 | 16.2 | 76.1 | 70.6 | 75.3 | |

| 21.3 | 21.8 | 21.0 | 88.9 | 89.6 | 88.0 | |

| 26.9 | 27.3 | 26.5 | 114.3 | 115.0 | 113.1 | |

| 33.7 | 34.2 | 33.3 | 139.7 | 140.0 | 138.5 | |

| 42.4 | 42.9 | 42.0 | 165.1 | 166.5 | 163.9 |

Table 7: Permissible Deviation in Outside Diameter in DIN 17172

| Nominal Outside Diameter-”D” (mm) |

Max.Permissible Diameter Variation | |

|---|---|---|

| Pipe Body | Pipe End | |

| D<200 | 1%(Values up to 0.5mm are permissible in all case) |

1%(Values up to 0.5mml. are permissible in A case) |

| 200 D<500 | 1% | 0.7% |

| 500鈮 | 1% | 1.6mm |

Table 8: Permissible Deviation in Outside Diameter in DIN 17176

| Manufacturing Process | Limit Deviation of Outside Diameter | |

|---|---|---|

| Cold Forming | 0.75% | |

| Hot Forming | 100mm | 0.75% |

| >100-320mm | 0.9% | |

| >320mm | 1.0% | |

Table 9: Permissible Deviation in Wall Thickness in DIN 28180

| Tube Outside Diameter | Permisible Deviations In Wall Thickness for Thicknesses | |

|---|---|---|

| Up to 2 | Exceeding 2 | |

| Tolerance of Classes I and 2 | 0.20 | 10% of Wall Thickness |

| Tolerance Class 3 | 0.20 | -10%, +15% of Wall Thickness |