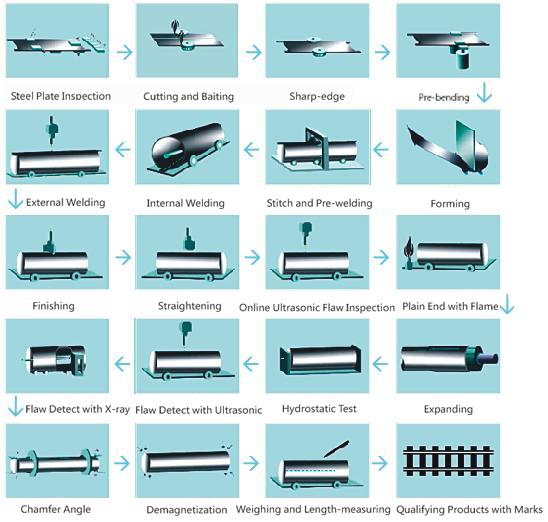

Longitudinally Submerged Arc Welded Process Flow

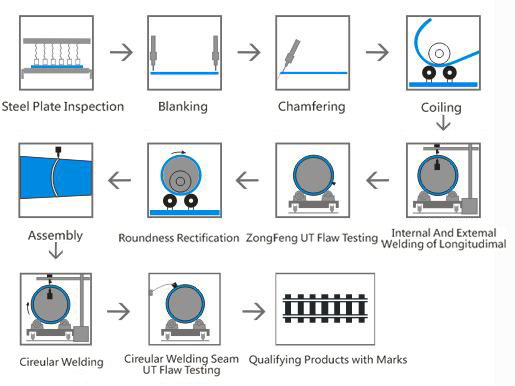

Roller Pipes Process Flow

Range of roller pipes: Outer diameter: Ф1200-3800mm | Wall thickness: 12-120mm | Unit length (max) 3.2m.

27SiMn Thick walled pipe

Large-diameter thick-walled seamless steel pipe

Size:1120×120-150, 630-1000×40-100, 530-630×40-100, etc.Material:10#, 20#, 35#, 45#, 16Mn, 27Simn, Alloy , etc.

UOE (Uing and Oing forming) Pipes

The UOE mill is the best suitable process to meet customers' requirements by virture of the characteristic of high production efficiency, stable product quality and various accessories for manufacturing and inspection. Manufacturing Process:

Manufacturing Process:

UOE (Uing and Oing forming) Pipes

Specifications

- Throughput: 400,000 MT

- Outside Diameter : Φ508-Φ1118mm (20"-44")

- Wall Thickness : 6.4-25.4mm (1/4"-1")

- Ouality Standards : API, BS, ASTM , JIS, DIN, GB , ISO, DNV

- Length : 9-12.2m (30'-40')

- Grades : GB/T9711 L190-L555 (API 5L A-X80)

- We are able to provide customers with quality products and perfect service.

- If you want to know more information, please kind to visit our website.

Manufacturing Process:

Manufacturing Process: