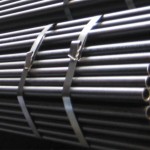

ASTM A192 Seamless Tubes

The ASTM A192 belongs to the carbon seamless tubes, which is specially designed for high, middle, low pressure purpose in seamless carbon steel boilers and as super heater tubes.

Chemical Composition of ASTM A192 seamless tube

| Grade | Chemical Composition (%) | |||

| ASTMA192 | C | Mn | Si | P, S |

| 0.06~0.18 | 0.27~0.63 | Max 0.25 | Max 0.035 | |

Delivery Condition: Annealed, Normalized, Normalized and Tempered

Surface treatment: Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test (Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension No-destructive Test.

Mechanical Properties:

| Grade | ASTM A192 MECHANICAL PROPERTIES | ||

| ASTMA192 | Tensile Strength | Yield Strength | Elongation |

| Min 325 | Min 180 | Min 35% | |

Seamless Carbon Steel Boiler Tubes for High-Pressure Service.

Standards: ASTM A192/A192M (ASME SA192/SA192M)

Size (mm):

- Outer Dimensions.: 19.05mm ~ 114.3mm

- Wall Thickness:2mm ~ 14 mm

- Length: max 16000mm

Application: Seamless Carbon Steel Boiler Tubes for High-Pressure Service.

Mill test certificates will be issued according to EN10204/3.1B

Packing: Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Inspection and Test: Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test, No-destructive Test, Hydrostatic Test.

Surface treatment: Oiled, black painted, shot blasted, hot dipped galvanized or phosphate coating.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.