Flange Bolt Specifications

A flange bolt differs from the common bolt in that it has a wider surface area under the head to provide for an even distribution of clamping pressure. This wider surface acts like a washer, eliminating the need to combine one with this kind of bolt. Flange bolts are available in numerous sizes, strengths, and configurations. Like most other types of fasteners on the market, metric flange bolts are available for any applications that require them.

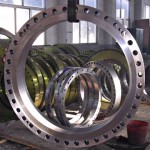

A flange is the name for the plate located at the end of a pipe, which connects to the flange of another similar pipe. This is accomplished by bolting the flanges together. Flanges usually have to be the same class to be bolted together. Flanges in the same class are made to the same pressure, temperature, size and tolerance specifications. Flange bolt specifications are also the same to allow a proper connection to be formed.

Class and Nominal Pipe Size

The flange bolt specifications are determined based on the class and nominal pipe size specifications for a flange. Any two flanges that share these two specifications also have the same flange bolt specifications. The class is a series of specifications a flange must match. These specifications are created by standardization bodies, such as the American Society of Mechanical Engineers (ASME) or American National Standards Institute (ANSI). Nominal pipe size is the thickness of the pipe the flange is connected to. The class does not dictate the nominal pipe size, so flanges in the same class can be different thicknesses.

Number of Bolts

The number of bolts indicates the number of flange bolts required to connect two flanges. There are always at least four bolts, no matter what size or class of flange is being used. The number of bolts increases when the nominal pipe size is increased. The number of bolts also increases as the class increases until Class 600, before it starts to decrease as the class is raised. This is because classes above 600 use thicker bolts. The thicker bolts reduce the number needed to seal the flanges.

Bolt Diameter

The bolt diameter is the diameter of the flange bolts that should be used to connect the flange. The diameter of the bolt is the stem diameter, not the head diameter. The flange bolt diameter can range from 0.5 inches to 3.5 inches. Flanges in higher classes or with larger nominal pipe diameters use thicker bolts.

Bolt Circle

The bolt circle is the diameter of an imaginary circle on the surface of the flange. This circle intersects the middle of all the bolt holes in the flange. The diameter of the actual flange is irrelevant for this measurement. The bolt holes in a flange are evenly spaced. Two flanges with the same number of bolt holes and the same bolt circle can be connected to one another. Flanges that might appear to be slightly different sizes may still fit together if they share the same bolt circle specification.

Specially designed flange bolts are equipped with anti-rotational “teeth” designed to “bite” or dig into the material one might need to fasten together. Similar to the locking rings one might see on a soda bottle or milk jug, these teeth on the flange bolt can be turned backward, but often require more force. This type of design is what makes a flange bolt uniquely and strategically different from a common bolt.

An essential addition to the flange bolt is the flange nut. While it is similar to an ordinary nut, one side of the flange nut is wider than the other to ensure even pressure distribution. The flange nut and flange bolt work well together, and in some cases may reduce costs by eliminating the need for purchasing separate washers. Proper torque on a flange bolt-nut combination will ensure that the fasteners never become loose by themselves. Only an outside force, such as a mechanic, can loosen these types of flange bolts.

The types of flanges one intends to bolt together do not necessarily require a special type of flange bolt, such as standard or metric. Instead, it is typically the physical size of a flange system, or the specific number of boltholes, that will indicate the required bolt size or grade one should use. The bolt grade indicates its strength, so the higher the grade a bolt has, the stronger it is. For example, high-pressure connections, such as in a steam line, may require grade eight bolts for the utmost reliability and safety.

A flange bolt is suitable with most any flange system. The sizes and grades, or strength ratings, can and will change depending on the application at hand. Sizes are available in standard or Society of Automotive Engineering (SAE) measurements, such as 1/4 inch and 1/2 inch, as well as metric measurements, such as 8mm and 10mm. Designed to hold connections tightly, without slippage or loosening, flange bolts are standard in most industrial applications where secure connections are crucial to production.