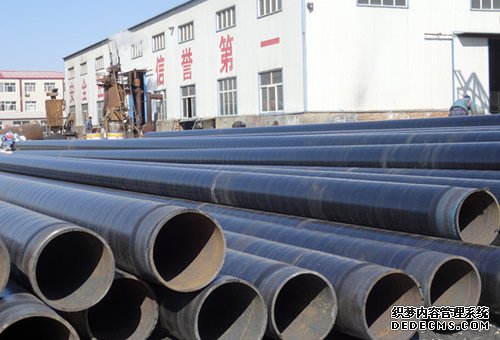

3PE anti-corrosion pipeline

TPCO

3PE anti-corrosion pipeline anti-corrosion materials, the outermost protective material, its intrinsic performance must ensure that the pipeline has more than a or even a life. Pipelines are mainly stacked, transported, buried three processes.

In the stacking transport process, the steel pipe to be exposed to the sun, rain and extreme cold, hot weather. Polyethylene plastic is cracked and degraded under direct sunlight, especially in the ultraviolet rays of the 300-320 nm wavelength. So to have more than a service life, polyethylene light resistance must be considered.

At the same time, polyethylene will also occur oxidation reaction, pipelines in the underground, underground soil sewage composition complex, electrochemical corrosion and surfactant, polyethylene can be accelerated by environmental stress cracking.

Comprehensive above to ensure that the steel pipeline has decades of service life, 3PE anti-corrosion materials must have the following performance.

A, excellent light resistance and mechanical strength, B, excellent environmental stress cracking resistance; C, excellent electrical performance. Anticorrosion installation company and most of the owners in the measurement of steel pipe quality, that the pipeline surface smooth, bright, black is good 3PE materials. The above analysis proves that this view is clearly not comprehensive enough. We have collected a number of production plants of 3PE anti-corrosion materials, individual batches have found that carbon black dispersion of the problem. Carbon black dispersion is not good, can not effectively block the sun in the ultraviolet attack, easy to cause the degradation of polymer materials, so the carbon black dispersion of anti-corrosion materials, a few years later the pipeline surface may appear cracks, this phenomenon in a short period of time is not easy to detect.

Anti-Corrosion Pipeline company to make their own product quality and protect the interests of owners, we must pay attention to the selection of anti-corrosion materials. 2.1 Focus on light resistance in order to prevent the Sun ultraviolet attack, anti-corrosion materials are generally using the best light resistance additive-carbon black. Carbon black in polyethylene plays a light shielding effect, so that light waves can not be passed from the carbon black layer, thereby protecting the polyethylene from ultraviolet attack. Resistance to photoelectric properties, cracking performance, mainly depends on the type of carbon black, carbon black content (2-2.4) and carbon black in the dispersion of plastics. This is the three major factors that affect the performance of polyethylene.

Required carbon black particle size is very small (less than 25nm), after the aging experiment proved: as the size of the increase in its light resistance will become worse. SY/T0413-2002 standard requirements of carbon black content (2-2.4), carbon black to evenly dispersed in the plastic, carbon black particle size smaller, the greater the cohesion between the particles, the more difficult to disperse. The above three factors, to achieve carbon black in the anti-corrosion materials in the dispersion, you can see the 3PE anti-corrosion materials manufacturer equipment and formulation process is mature. Of course, 3PE manufacturers use large particle size of carbon black, then another argument, because the size of the carbon black is more easily dispersed. But the light resistance and a variety of properties with the size of the increase and change, so, 3PE manufacturers, in addition to the selection of suitable polyethylene model as the main material, carbon black model size, should be 3PE anti-corrosion material manufacturers Choose carbon black must be ensured. Carbon black dispersion of the inspection, in the pipeline Anti-Corrosion company is easy to carry out, cost less, easy to operate, easily mastered, using standard picture control is very intuitive. Set up this test means, as long as this performance can pass, 3PE anti-corrosion material carbon black content and particle size guarantee within the specified value.

The rest of the performance-anti-aging, mechanical, electrical properties may be assured that the quality of the product can be more than 20a or longer.

上一篇:Analysis on the phenomenon of slag inclusions during welding

下一篇:Identification method of thick-walled seamless steel pipe